Seven reasons to choose aluminum for your project

1. Flexibility

Aluminum is highly flexible, allowing it to be shaped into various forms and dimensions, making it ideal for complex designs in architecture and engineering.

2. Affordability

Aluminum is relatively inexpensive to produce, which means it can be used in lightweight designs without increasing costs. This makes aluminum a cost-effective choice for modern projects.

3. High strength-to-weight ratio

Aluminum Alloy has a superior strength-to-weight ratio compared to steel, which is particularly beneficial in lightweight applications such as automotive and structural engineering.

4. Good Thermal Conductivity

Aluminum has excellent thermal properties, making 6061 thermal conductivity a preferred material for applications requiring efficient heat dissipation, such as in electronics and building structures.

5. Resistance Corrosion

Aluminum surfaces are resistant to direct contact with other materials, which is crucial for maintaining corrosion resistance in industrial and construction settings.

6. High Performance Coating

Aluminum can be anodized and high-performance coatings can be easily applied to further improve its corrosion resistance.

7. Recyclability

Aluminum does not require cutting down trees like wood. It is also highly recyclable.

Aluminum Alloy in Application Areas:

Aluminum profile is a popular choice for:

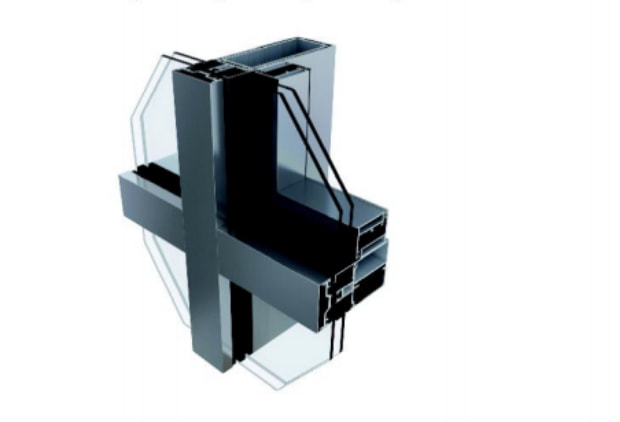

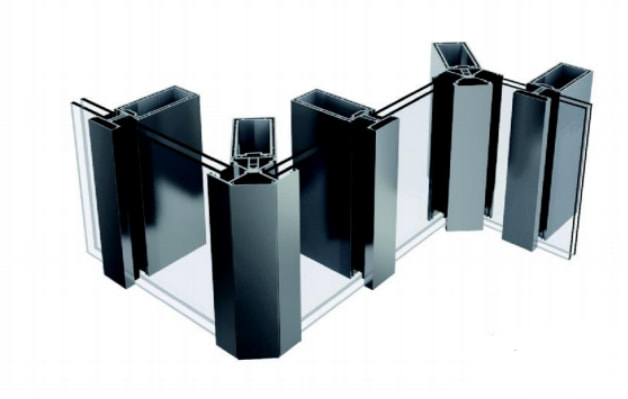

custom extrusion applications Curtain Wall System

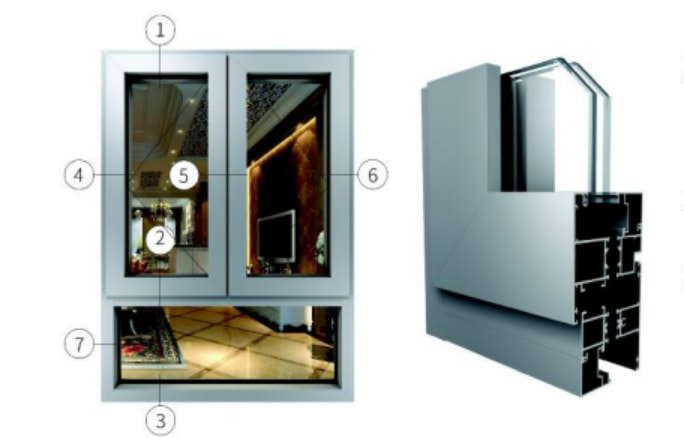

custom extrusion applications Windows and Door System

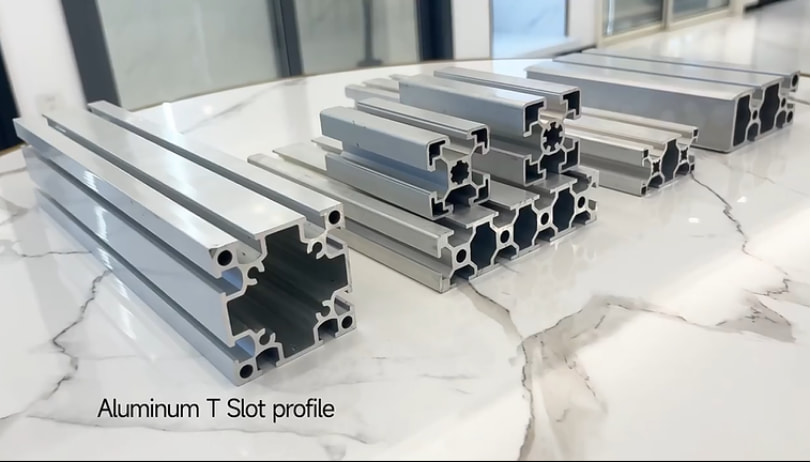

Assembly line aluminum profiles, workbench frames, robot protection devices, safety fences, material racks, trolleys, clean rooms, etc.

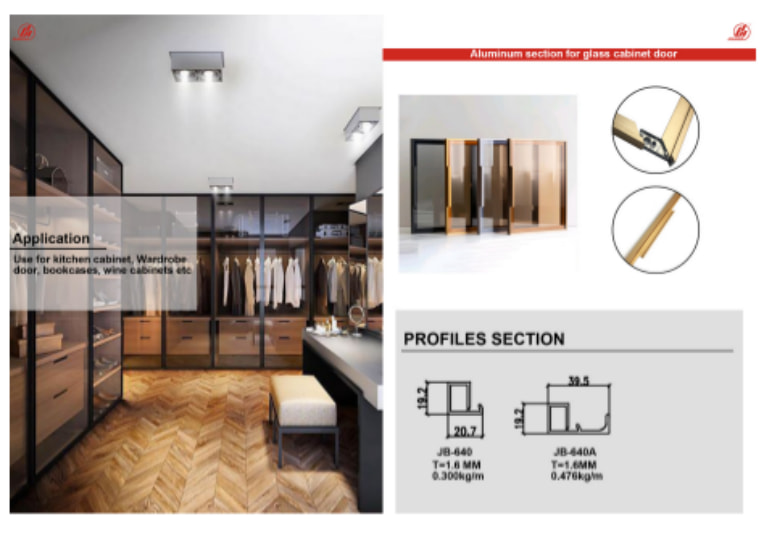

Furniture and cabinets (eg handles, hinges, supports)

Transportation: airplanes, trains and buses (e.g. armrests, luggage racks, seats)

Communication equipment (e.g. mobile phone cases, laptop cases, etc.)

What are the commonly used aluminum alloys in the field of mechanical manufacturing?

In the field of mechanical manufacturing, common aluminum alloy grades include: aluminum alloy , 6063, 7075, 6060,2014,6061, etc. Each grade has different performance characteristics and is suitable for specific application scenarios.

6063 aluminum alloy:

Features: 6063 aluminum alloy is a commonly used aluminum alloy with good plasticity and surface treatment performance. It is suitable for extrusion manufacturing of complex cross-sections and easy to weld. It is not only suitable for the industrial field, but also a commonly used aluminum alloy for architectural decoration. Its main applications include: automation equipment, mechanical parts, aluminum profile radiators, structural aluminum profiles, window frames, door frames, architectural decoration, etc.

7075 aluminum alloy:

Features: 7075 aluminum alloy is a high-strength heat-treated aluminum alloy with good tensile strength and fatigue resistance. Suitable for mechanical parts with high strength requirements.

Applications: Aerospace, high-strength mechanical parts, bicycle frames, etc.

2014 aluminum alloy:

Features: 2014 aluminum alloy is a high-strength heat-treated aluminum alloy with good wear resistance and corrosion resistance. Suitable for mechanical parts with high strength and wear resistance requirements.

Application: Aircraft and automobile parts, bearing parts, etc.

6060 aluminum alloy:

Features: 6060 aluminum alloy is an aluminum alloy suitable for extrusion forming, with good plasticity and surface treatment performance. Suitable for extruded aluminum profile manufacturing.

Application: Structural aluminum profiles, architectural decoration, automotive parts, etc.

6061 aluminum alloy:

Features: 6061 aluminum alloy is a heat-treated aluminum alloy with good machinability, weldability and mechanical properties. It has high strength and is suitable for manufacturing mechanical structures, aviation parts, bicycle frames, automobile parts, etc.

Conclusion:

With all these advantages and potential applications, you may decide that aluminum extrusions are a good fit for your project. If so, we are here to help. Learn more about our aluminum extrusion capabilities.