How to choose the right aluminum profile for furniture application?

In modern furniture design, aluminum profiles are increasingly favored by designers and manufacturers due to their advantages such as light weight, high strength, corrosion resistance and beauty. This article will explore in depth the key factors and methods for selecting aluminum profile for furniture to help customers make wise decisions.

Advantages of aluminum profiles in furniture

Lightweight and high strength: Aluminum profiles have a good strength-to-weight ratio, making the furniture both light and strong, easy to move and install.

Corrosion resistance: Aluminum profiles have a natural anti-oxidation layer, which shows good corrosion resistance in various environments and prolongs the service life of furniture.

Processability: Aluminum profiles are easy to cut, drill, weld and surface treat, suitable for a variety of processing techniques, and meet personalized design needs.

Aesthetics: After surface treatments such as anodizing, aluminum profiles have beautiful appearance and modern feel, suitable for a variety of furniture styles.

Recyclability: Aluminum is recyclable, environmentally friendly, and meets people's demand for sustainable development.

Key factors in choosing aluminum profiles

Environment of furniture

The use environment of furniture has an important influence on the selection of aluminum profiles. For example, outdoor furniture needs to withstand wind, sun and rain, requiring aluminum profiles to have good corrosion resistance and oxidation resistance. Commonly used aluminum alloys are 5052 and 6063, which perform well in outdoor environments.

5052 aluminum alloy: has good corrosion resistance and medium strength, suitable for outdoor furniture.

Aluminum alloy 6063: has good extrusion performance and surface treatment effect, suitable for indoor and outdoor furniture.

Mechanical properties

According to the function and load-bearing requirements of the furniture, choose aluminum profiles with appropriate mechanical properties. For example, load-bearing furniture such as bed frames and sofa frames require higher strength and hardness, and 6061 aluminum alloy can be selected; while decorative furniture such as display racks and bookcases pay more attention to appearance and formability, and aluminum 6063 can be selected.

6061 aluminum alloy: It has good mechanical properties and machinability, suitable for structural parts and frames.

Aluminum alloy 6063: It is suitable for furniture that requires a beautiful surface and is easy to process.

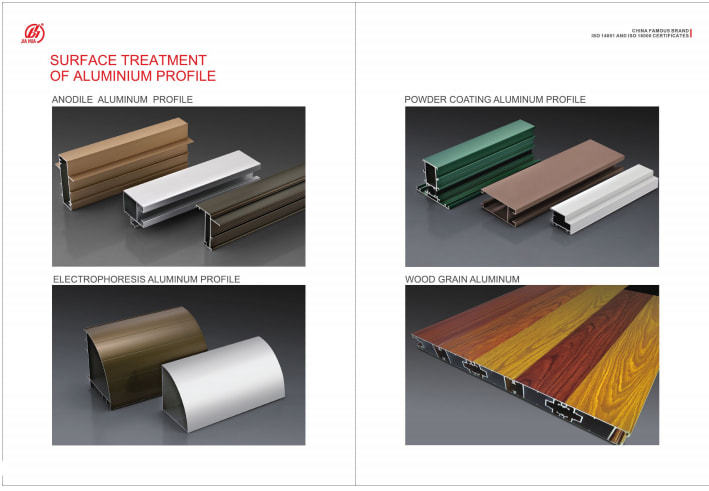

Surface treatment

The surface treatment of aluminum profiles not only affects the appearance of the furniture, but also its durability. Anodizing, electrophoretic coating and powder coating are common surface treatment methods, each with its own advantages and disadvantages. After anodizing, a dense oxide film is formed on the surface of the aluminum profile, which improves corrosion resistance and wear resistance, and gives it a variety of color options.

Anodizing: Enhances corrosion resistance and wear resistance, and provides a variety of color options.

Electrophoretic coating: Provides uniform coating with good adhesion and corrosion resistance.

Powder coating: Provides rich color and texture options, good wear resistance and corrosion resistance

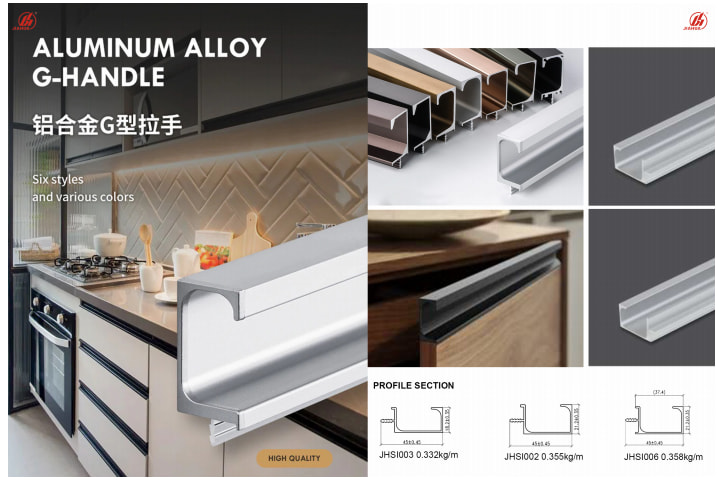

Aesthetics

The design of furniture requires not only functionality, but also aesthetics. The appearance treatment and color selection of aluminum profiles have an important impact on the overall visual effect of furniture.

Cost-effectiveness

On the premise of meeting performance requirements, choosing cost-effective aluminum profiles can reduce production costs and improve the market competitiveness of products. For example, aluminum alloy 6063 is a common choice for furniture manufacturing, while meeting aesthetic and performance requirements, and the price is relatively low.

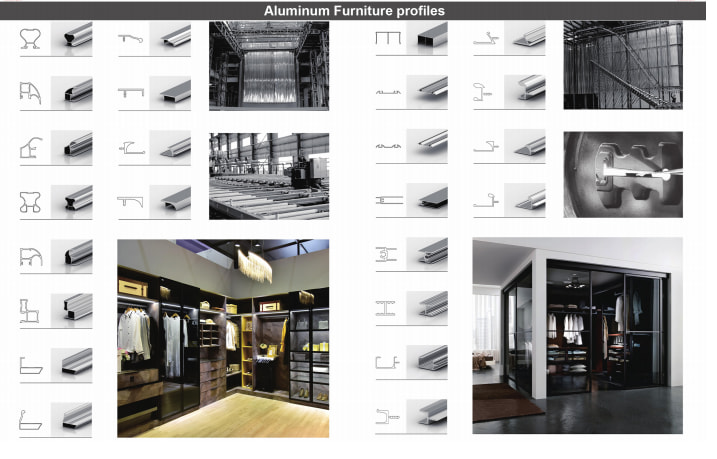

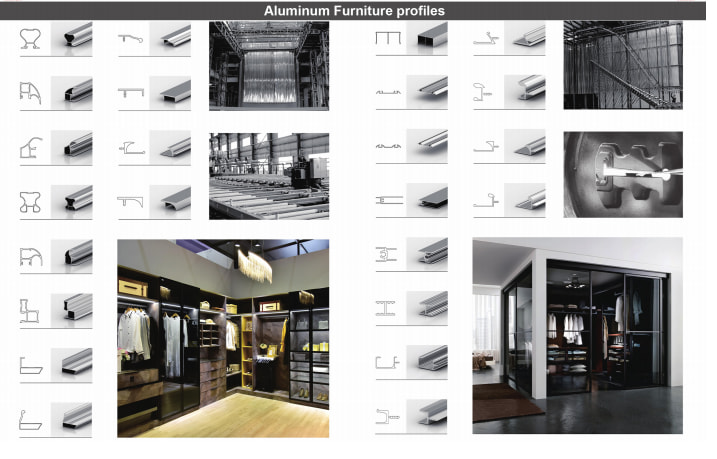

Application of aluminum profiles in different furniture

1. Tables and chairs

The frames of tables and chairs require light but strong materials, and 6061 and 6063 aluminum alloys are commonly used. Aluminum alloy 6063 is often used for chair frames and table borders or decorative strips due to its good surface treatment effect.

2. Cabinets and lockers

Cabinets and lockers require materials with good corrosion resistance and aesthetics, and 5052 and 6063 aluminum alloys are commonly used. 5052 aluminum alloy has good corrosion resistance and is suitable for cabinets in kitchen and bathroom environments.

3. Bed frames and sofa frames

Bed frames and sofa frames require materials with strong load-bearing capacity, and 6061 aluminum alloy is commonly used. 6061 aluminum alloy has good mechanical properties and machinability, and can provide stable structural support.

4. Bookshelves and display racks

Bookshelves and display racks require materials with good formability and aesthetics, and aluminum alloy 6063 is commonly used. After anodizing, aluminum alloy 6063 has a beautiful appearance and is suitable for display purposes.

In furniture applications, choosing suitable aluminum profiles requires comprehensive consideration of application environment, mechanical properties, surface treatment, aesthetics, and cost-effectiveness. Reasonable selection and application of aluminum profiles can not only improve the performance and durability of furniture, but also enhance its aesthetics and market competitiveness.If you want to know more about aluminum furniture product,please feel free to contact us.We are an aluminum profile manufacturer with 30 years experience.