R&D Team

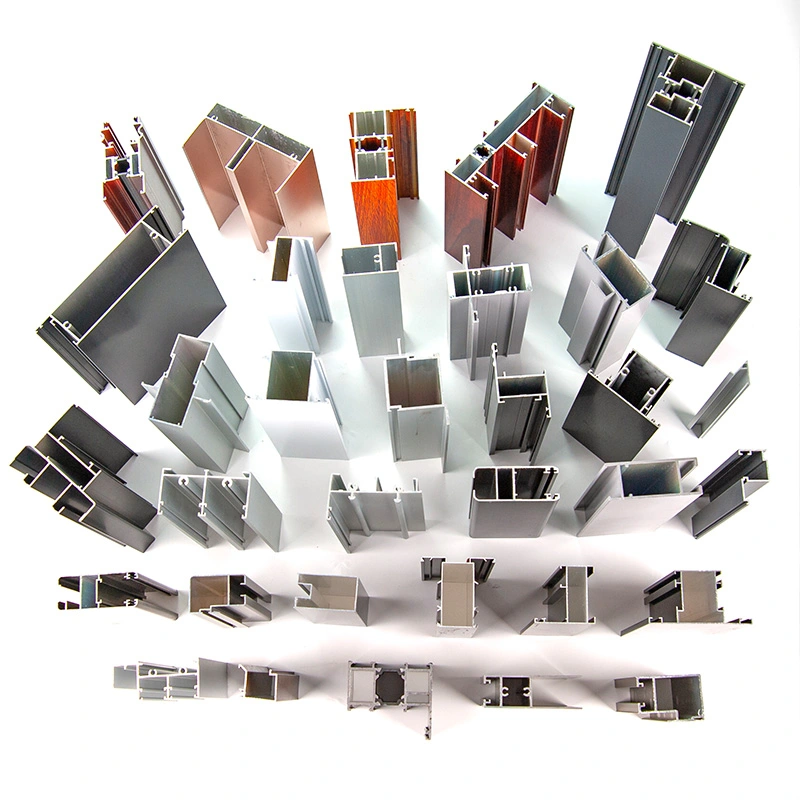

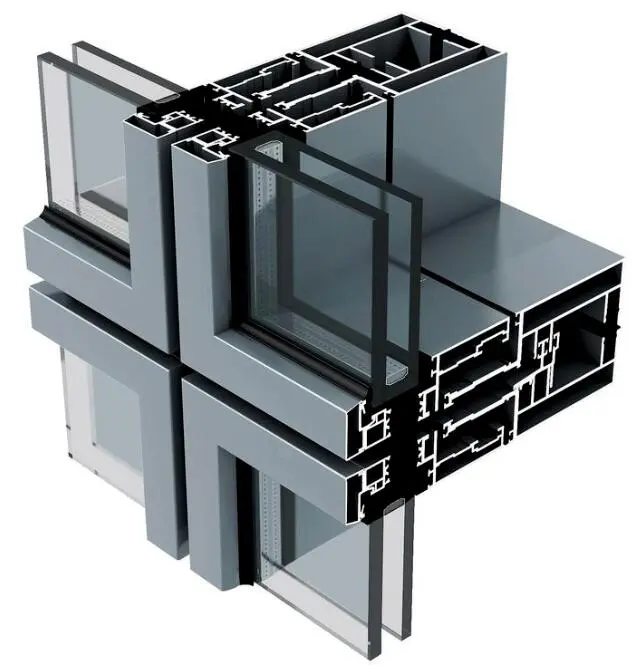

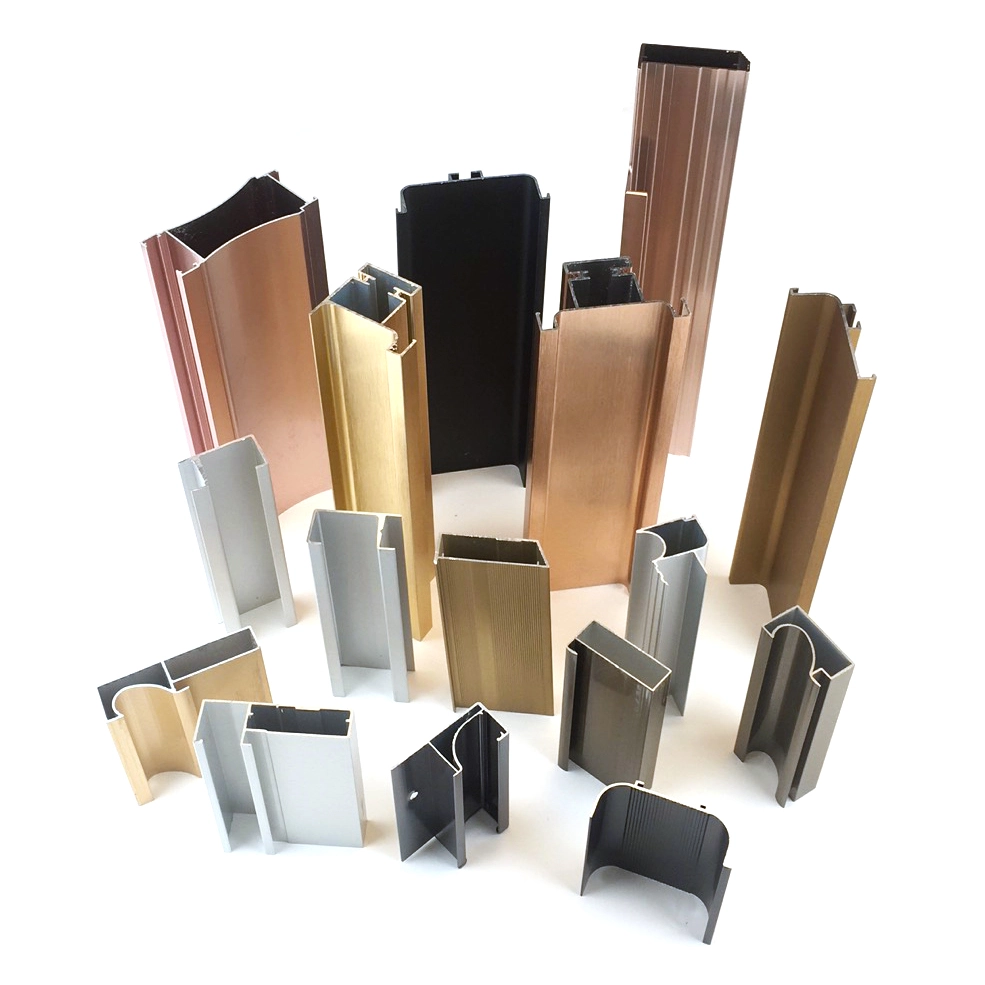

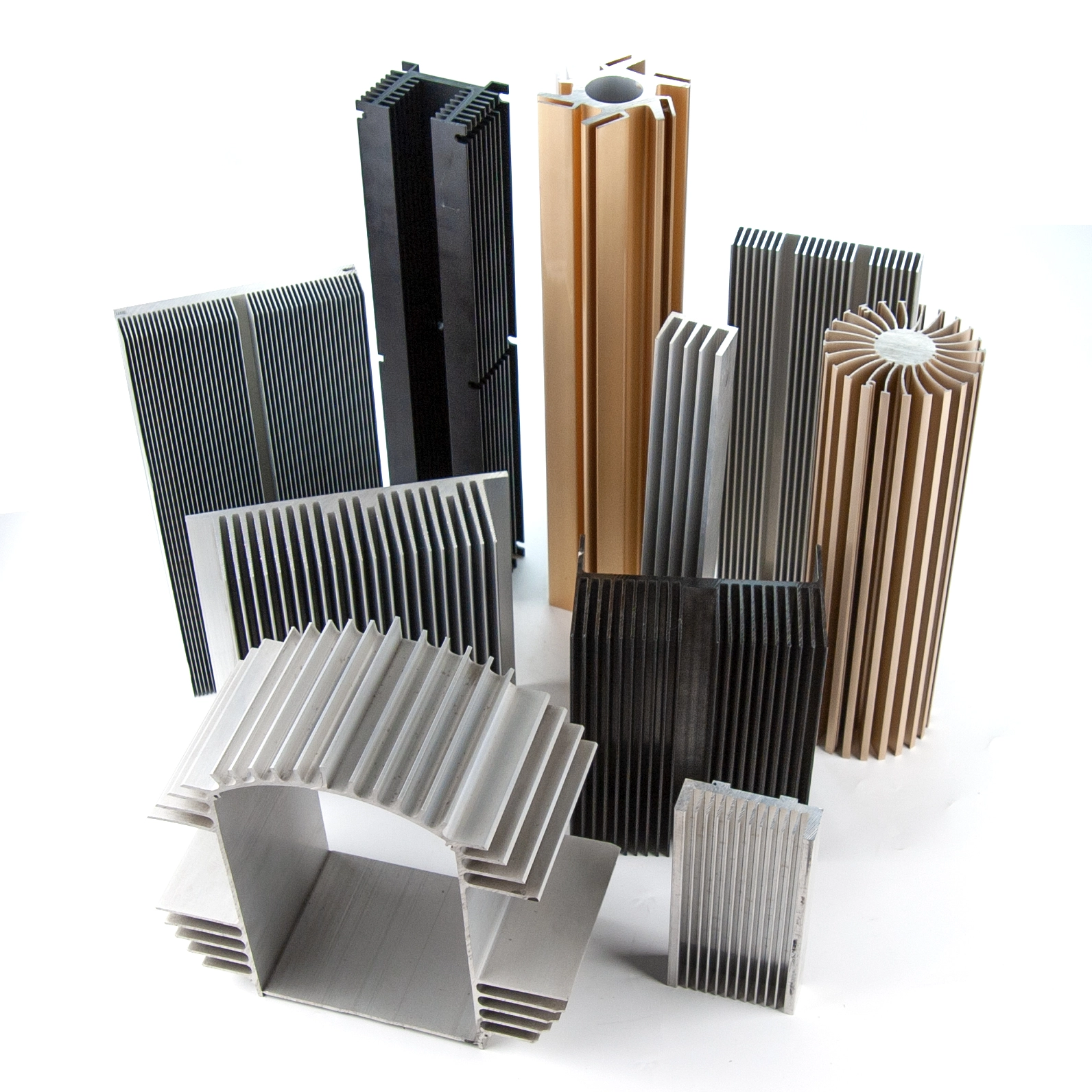

- profession and 35 years experience R&D team

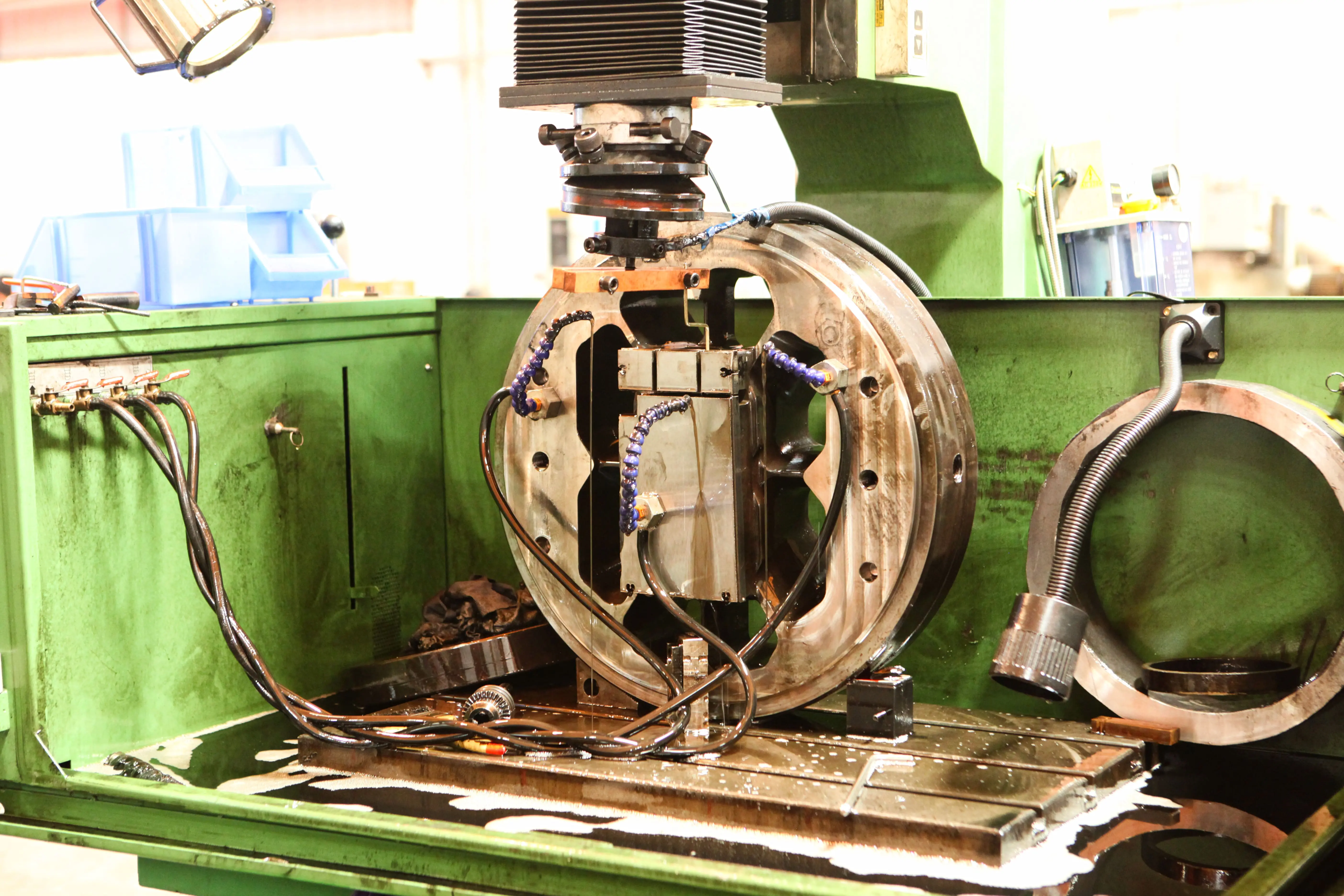

- High -tech CNC machines for making mold

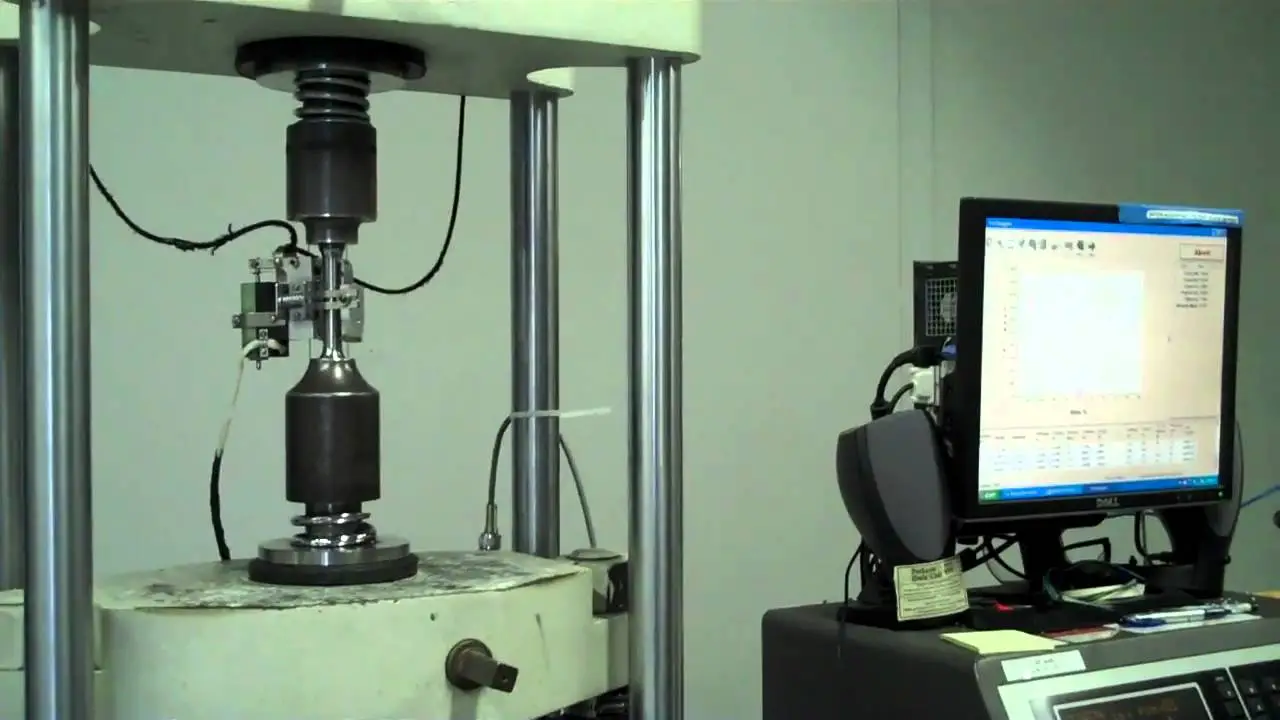

- Diemension is higher precision

- Faster to receive samples , take around 10-14 days

- Provide your aluminum profile design suggestion

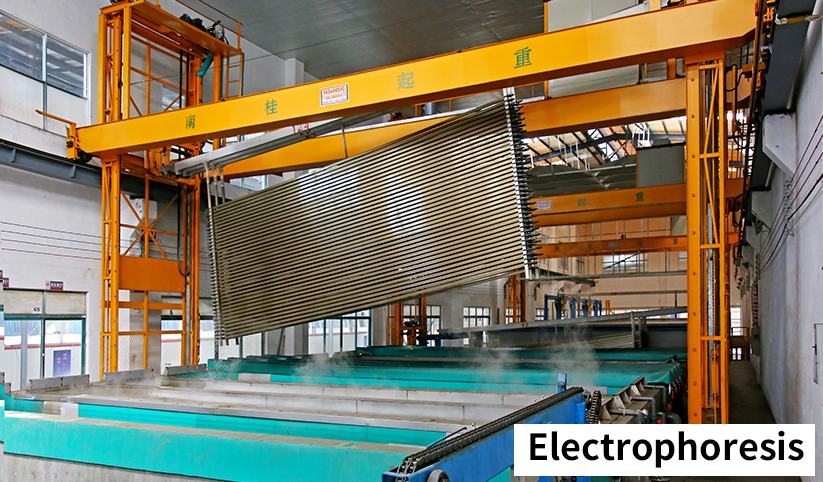

- Avoid the die line with our high techonogy during desginig the mold